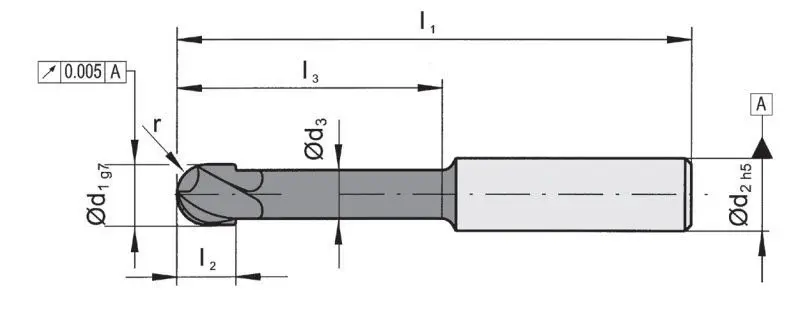

roughing end mill diagram

The rolling parameters were adopted from the No. The tooth design allows for little to no vibration but leaves.

Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded.

. The fine-pitch end mills leave a better finish and. Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts. Using Traditional Roughing.

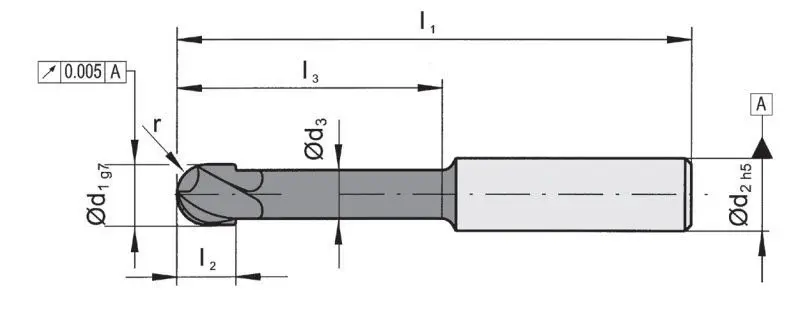

Ball nose cutters or ball end mills lower row in image are similar. The dimensions of the components are listed in Table 1. Cutting edges are only on a top.

Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2. Design that Virtually Eliminates Flute Packing and Obstruction.

Fine-pitch scallops are smaller and better for lighter cuts in hard materials. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Drill A tool for drilling.

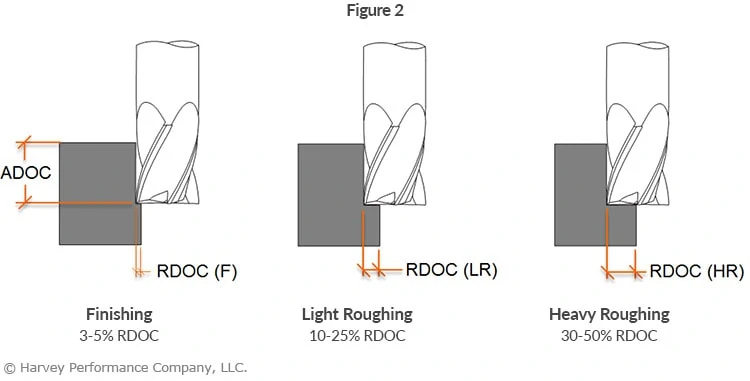

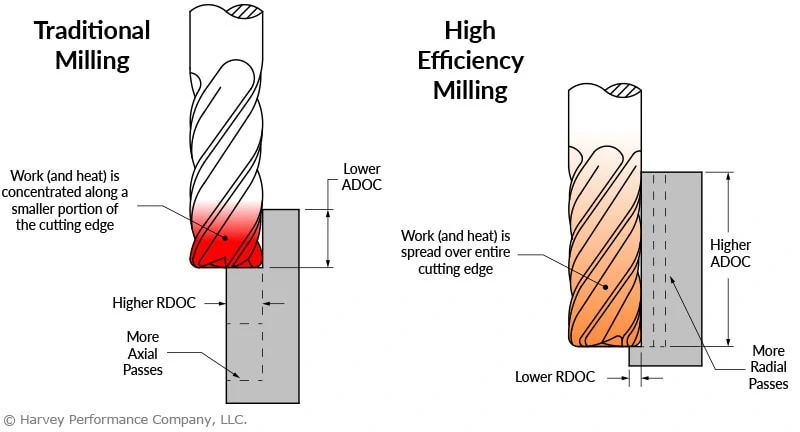

Carbide Square End Mills. Cutting Diameter The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM.

Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard. 45 for Trochoidal Toolpathing. Coarse tooth roughing end mills remove large chips for heavy cuts deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. A ball end mill is constructed of a round cutting. Endmills are available in a wide variety of.

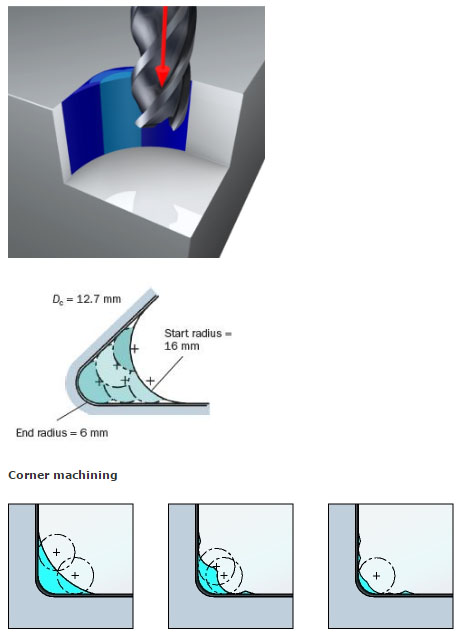

Haas roughing end mills come in fine- and coarse-pitch versions. Scallop diagram of high feed mill and ball end mill with the same workpiece engagement full slotting. 35 for light duty CNC Machines.

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. Up to 16 cash back 34 Diam Fine Pitch 2 LOC 4 Flute Cobalt Roughing Square End Mill TiAlN Finish 4-14 OAL 34 Shank Diam Single End 30 Helix MSC 45534674 Niagara Cutter 17014843 In Stock. End Mill Definitions.

End mill A multi. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. As you can see a chain of holes are plunged vertically with the tool to rough out most of the.

35 for light duty CNC Machines. 45 Ball Nose End Mill. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is.

Corner radius end mills have a rounded cutting edge and are used where a. Tertiary 3rd Additional relief clearance provided adjacent to the secondary. The graphic shows a typical plunge milling operation for a square pocket courtesy of BobCAD.

HEM is a roughing technique. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form. Heavy cuts can be achieved because our roughing end mills have a much higher. The width were given to the.

45 for Trochoidal Toolpathing. 2 roughing mill in CSC and are summarized in Table 2. 5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill.

Cnc Programming Examples G91 Incremental Programming Tutorials Programming Dibujo Tecnico Ejercicios Tecnicas De Dibujo Electricidad Y Electronica

Milling Archives Page 2 Of 3 Harvey Performance Company

Milling Archives Page 2 Of 3 Harvey Performance Company

The Complete Guide To Plunge Milling And Roughing

Entry Door Jamb Width Illustration Common Jamb Sizes 4 9 16 5 1 4 Or 6 5 8 Typical 2x4 Is A Exterior Door Frame Installing Exterior Door Exterior Doors

Sanrico Carbide End Mill End Mill Wood Drill Bits Non Ferrous Metals

G90 And G91 G Codes Cnc Programming Arduino Cnc Coding

Ball Nose Endmill Dsk Series Paul Horn Solid Roughing For Steel

Schematic Layout Of Industrial Hot Rolling Mill Process Download Scientific Diagram

Roughing End Mill Kyocera Unimerco

Mortise Gauge Plan Locking Screw Version Easy Woodworking Projects Woodworking Projects Plans How To Plan